Join The Advanced Composite Machining Revolution

Machine your composites...

Safely

Eliminate health and safety issues with Compcut’s fully enclosed automated process.

Cleanly

No need for a specially ventilated area – with no dust to contend with you can even cut composites in a lab.

Learn more...

Quickly

Test coupons can be cut in under a minute and go straight from cut to test.

Learn more...

Easily

Free up your skilled personnel – Test coupons can be easily cut with no specialist skills involved.

Learn more...

Reliably

Take control of your composite test coupon, prototype and production machining process.

Learn more...

In the Lab

Eliminate the need for a special “dirty” cutting area that has to be ventilated and cleaned.

Learn more...

Cost Effectively

Reduce costs, increase efficiency and improve productivity.

Learn more...

With Environmental Responsibility

Use less energy and

produce less scrap.

Learn more...

With Consistent Precision

Eliminate coupon and part rejection and ensure consistent test results and outputs.

Learn more...

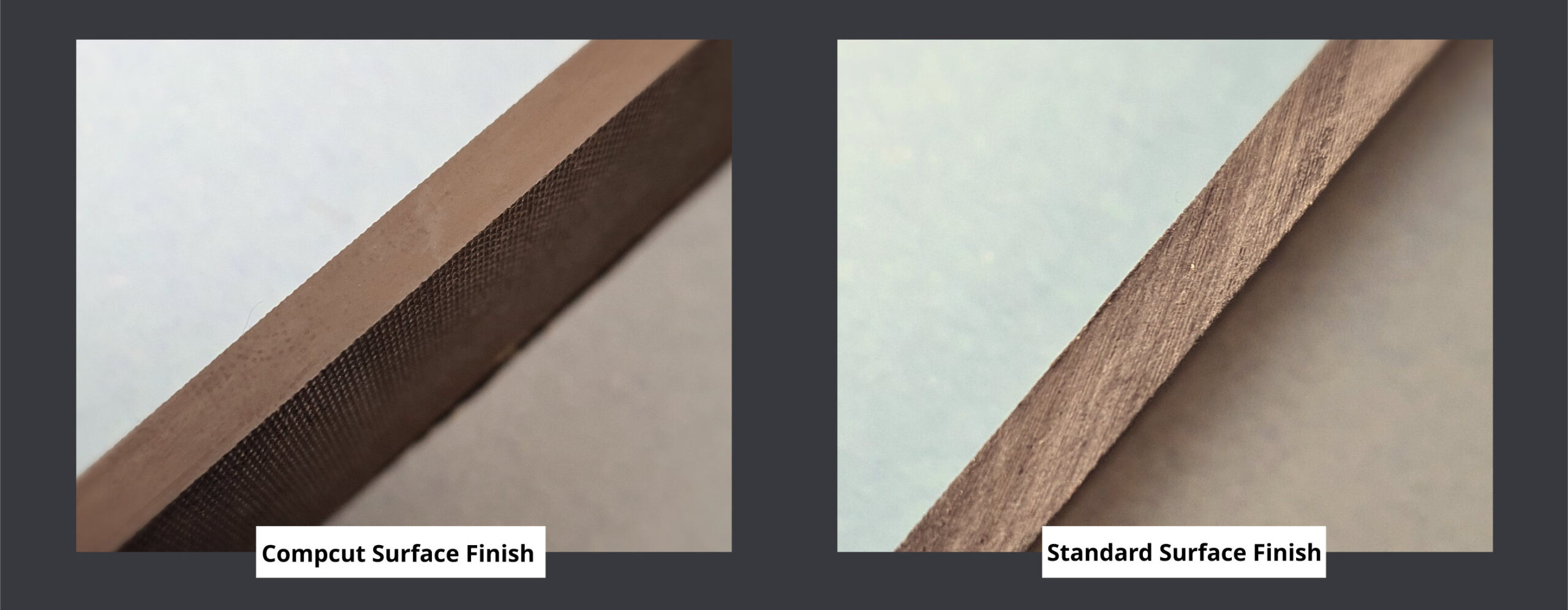

Consistent test ready coupons straight from the machine

Excellent Surface Finish

Accurate Perpendicularity

Class Leading Parallelism

Book a cutting trial, or a machining demonstration

For an advanced composite machining demonstration, send us some of your materials and we can produce some test coupons for you, or alternatively you can book an onsite demonstration.

Compcut Delivers

Value For Everyone

Click On Your Job Function Below To Learn How Compcut's Advanced Composite Machining Can Help Your Team

Facilities Management

Health & Safety Management

“The exceptional accuracy of our Compcut saw has enabled us to reduce the amount of waste material generated..."

Professor, Dr Markus Grob

Head of the Institute of Polymer Engineering

FHNW – University of Applied Sciences Northwestern Switzerland

Financial Mangement

“The Compcut saw has established itself as a vital resource for the cutting and machining of the composite materials used across all our activities, and we have been more than satisfied with its performance.”

Dave Wood

Technical Supervisor (Laboratories)

Department of Mechanical Engineering

University of Bath

Procurement Team

“Quality has always been a cornerstone of PRF, and we are continuing to invest in our in-house R&D by growing our team and supporting them with highly accurate tools such as the Compcut saw.

Robert Burnell, CEO

PRF Composites

Lab & Workshop Management

"The Compcut saw is a major factor in ensuring the reliable consistency of our test results”

Dr Geraint Havard

Composite Manager

R-Tech Materials

Senior Management

“The Compcut saws cut test specimens to such a high quality edge finish that no post preparation is required”

Paul Yeo

Managing Director

Composite Test and Evaluation (CTE)

Corporate Social Responsibility Team

“The exceptional accuracy of our Compcut saw has enabled us to reduce the amount of waste material generated in the production of test samples, which is an important step for us and for the environment.”

Professor, Dr Markus Grob,

Head of the Institute of Polymer Engineering

FHNW - University of Applied Sciences Northwestern Switzerland

Quality Mangement

“Compcut has enabled us to consistently produce high quality test samples..."

Alix Sauget

Research & Development Manager

SHD Composite Materials Ltd

Don't See Your Job Function?

Our Customers Say

View Our Advanced Composite Machining Range

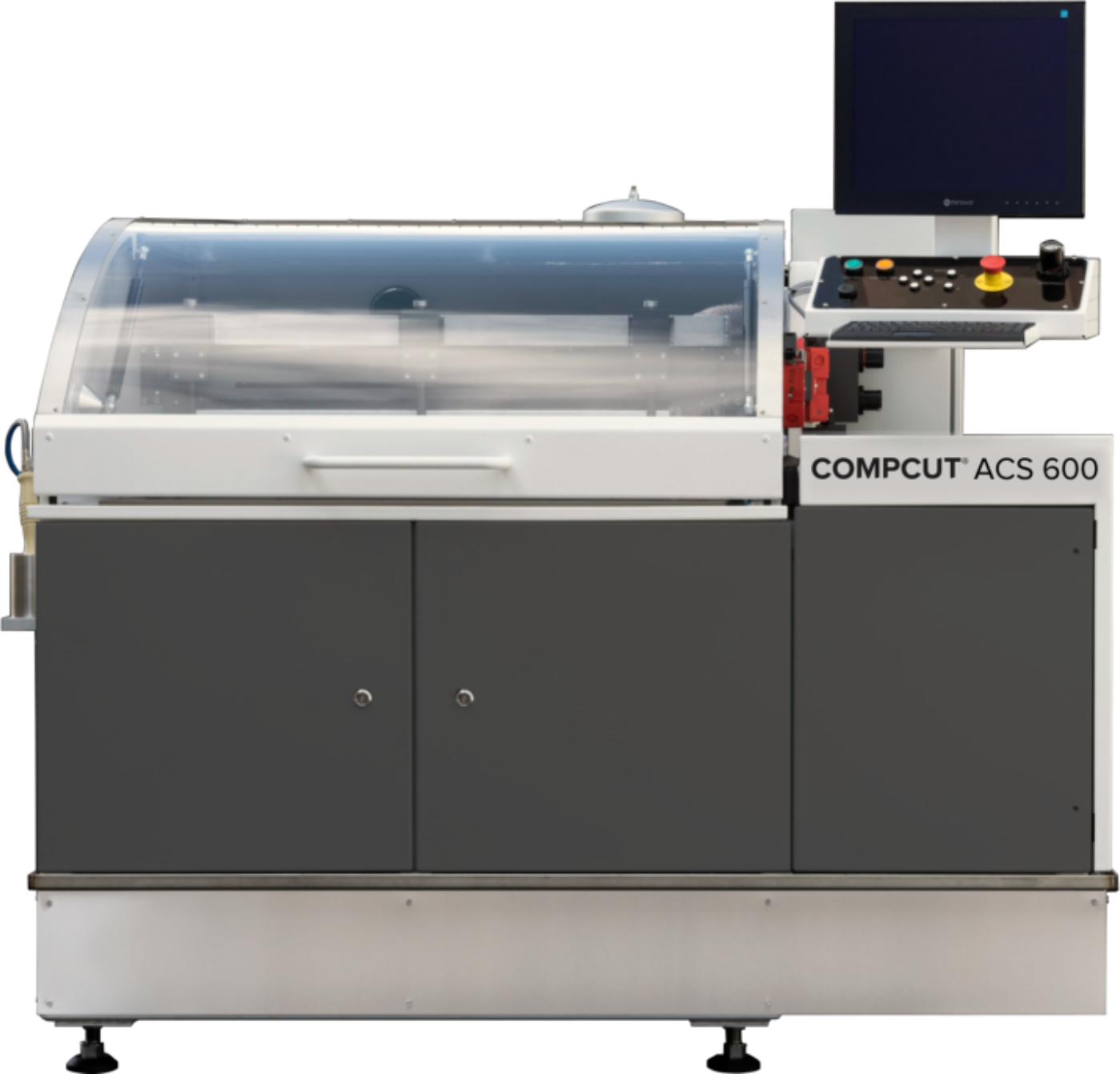

Linear Cutting

Compcut ACS 300

Compcut ACS 600

Compcut ACS 1200

Complex Geometry Cutting

Compcut PCR 300

Compcut PCR 600

Compcut PCR 1200