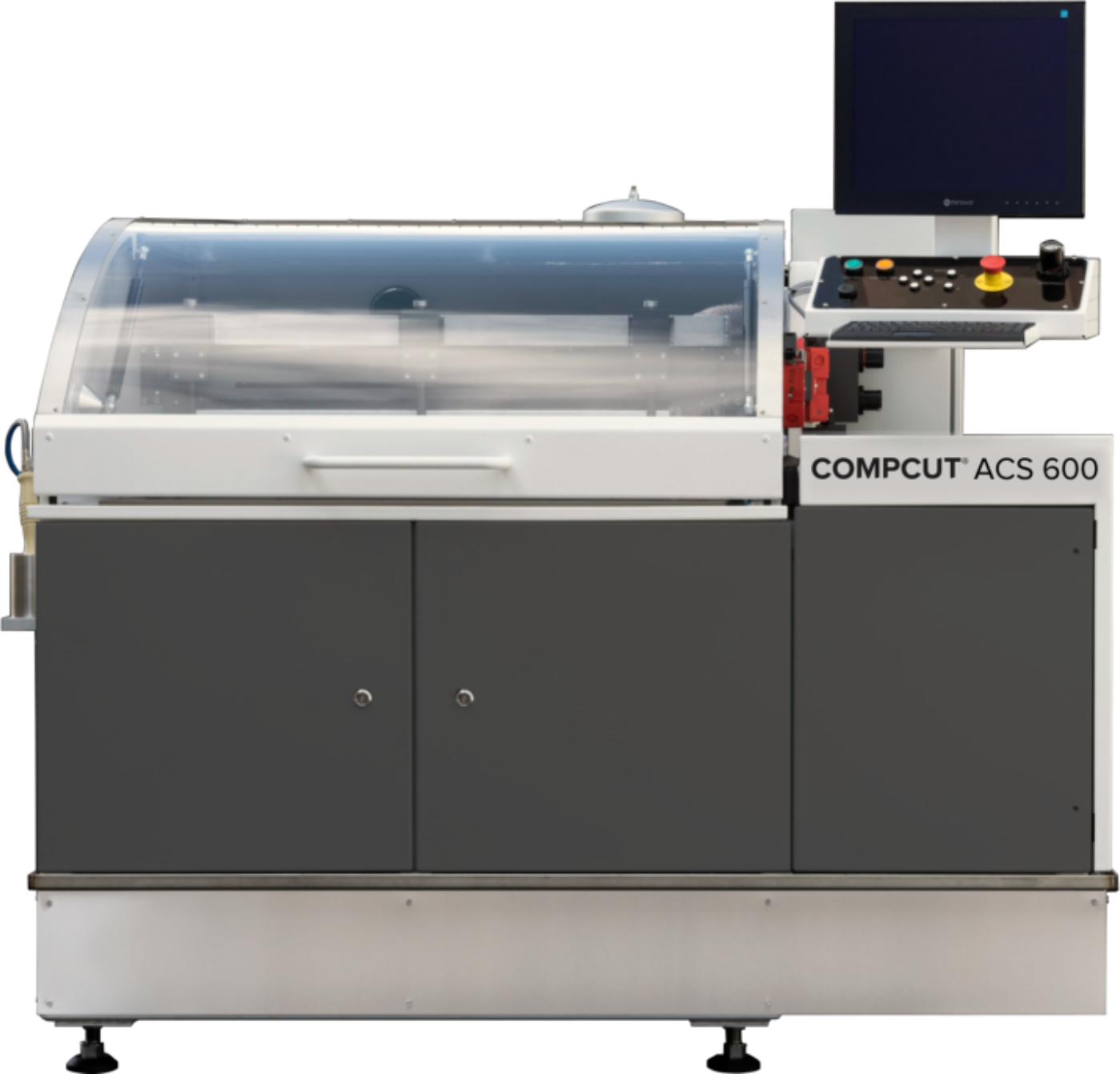

Compcut ACS 600

The Compcut ACS 600 advanced composite plate saw achieves precise cutting in a diverse range of materials to prepare highly accurate composite test specimens. This is our mid-range sized machine – with a clear panel size of 600 mm x 600 mm – medium to large laminate sizes and test specimens.

600 x 600 MM

Cleared Panel Size

4500 RPM

Max Spindle Speed

2.4 KW

Spindle Power

CNC MATERIAL FENCE

- Pneumatic sheet clamps to clamp a wide range of materials

- Automatic positioning for repeat production without user intervention

- Dual driven for exceptional perpendicularity & parallelism

- Repeatable

CROSS-CUT CARRIAGE

- Rigidity of X-axis assembly provides superior surface finish

- Clear working area with cutting head below the table

- Easy blade change

- Servo-driven ball screw provides smooth and accurate cutting feed

BAR CLAMP WITH COOLANT

- Both laminate and cut specimen are secured during the cutting process

- Constant flood cooling across entire cut length

USER INTERFACE CONTROL SYSTEM

- Conversational CNC permits ease of use

- Part-programmable for automatic machining

- Material parameters store best feed and spindle speeds for each laminate

- Remote support available

COOLANT SYSTEM

- Bag-based filter system for easy maintenance

- Washdown lance for easy cleaning

- Recirculating or a 100 loss systems

- Able to use multiple coolants

SAFE WORKING ENVIRONMENT

- Fully enclosed work area

- Connection to external dust extractor

- CE marked to relevant standards

- Fully interlocked system

- Bag-based filter system for easy maintenance

SPECIFICATIONS

| Material Capacity | |

|---|---|

| CLEARED PANEL SIZE | 600 X 600 MM @ 20 MM 500 X 500MM @ 50 MM |

| MATERIAL THICKNESS/CUT DEPTH* |

0 – 50 MM / 0 – 100 MM |

|

FRONT SPECIMEN TABLE |

400 MM |

|

COOLANT CAPABILITY |

FLOOD COOLANT WITH BAG FILTER |

| Enclosure | |

|

ENCLOSURE |

FULLY ENCLOSED – EXTRACTABLE |

| Spindle | |

| SPEED | 2000 TO 4500RPM |

| SPINDLE POWER | 2.4KW |

| BLADE SIZE | 200 – 300MM |

| BLADE THICKNESS | 1.5 – 4.5MM |

| Speeds | |

| RAPID SPEEDS X,Y,Z | 150MM/S |

| CUTTING SPEEDS | 0.1 – 40MM/S |

| Accuracy, Perpendicularity, Parallelism | |

| TYPICAL SPECIMEN PERPENDICULARITY | 0.03 MM |

| TYPICAL SPECIMEN PARALLELISM / 100MM* | 0.03 MM |

| TYPICAL SPECIMEN PARALLELISM / 300MM* | 0.04 MM |

| TYPICAL SPECIMEN PARALLELISM / PANEL | 0.07 MM |

|

TYPICAL SPECIMEN DIMENSIONAL ACCURACY |

0.05 MM |

|

TYPICAL SPECIMEN PARALLELISM Z PLANE |

0.03 DEG |

| External Dimensions: (W)x(D)x(H) | |

| WIDTH* | 1870 MM |

| DEPTH* | 1920 MM |

| HEIGHT* | 1650 MM |

| Required Services | |

| POWER | 415V 3PH 32A |

| AIR – DRIED & FILTERED | 70- 125 PSI |

| EXTRACTION | APPLICATION SPECIFIC |

CUTTING THROUGH COVID

SUPPORTING PRACTICAL RESEARCH AT THE UNIVERSITY OF BATH

The University of Bath’s Department of Mechanical Engineering took delivery of their Compcut 600 advanced composite saw back in May 2020, right in the middle of the first COVID 19 Lockdown period.

Despite this challenging début and continuing Covid disruptions to Higher Education provision, the Mechanical Engineering Technical team has managed to bring the unit into effective service, supporting a wide range of academic work and practical projects.

The Compcut 600 had been very carefully selected as the ideal machine to create high quality, multiple and consistently accurate Carbon Fibre coupons, to not only support the department’s composite related research activity but also to be available for resourcing a wide range of student’s projects including ‘high profile’ design, development and build competitive student team initiatives.

The University is currently actively involved in a range such multi-discipline student led competitive initiatives including, Bath Zero Electric Motorcycle which involves extensive testing of fairings and other vital parts that contribute to the construction of the ‘all electric’ superbikes.

The Bath Zero project was set up in 2014, with the specific aim to enter (with success) in the MOTO E and Isle of ManTT Zero Class competitions. Similarly, the multi-discipline student Team Bath Drones initiative was established in 2015 to meet the IMech E challenge for the design, build and testing of unmanned aerial systems which requires the highly accurate testing of outer shell and rib support structures that make up these very varied and complex vehicle designs.

The Mechanical Engineering department had been able to identify the Compcut 600 as meeting their specification requirements both through web based research and importantly through recommendation from nearby the Bristol Composites Institute at the University of Bristol where members of Bath’s Composites Technical Team, Steve Thomas and Mark Wellman were able to visit and observe at first hand the Compcut in everyday operation – to assess its performance and capabilities in a practical setting.

Steve Thomas a member of the department’s technical team comments, ‘Our extensive research led us to the Compcut 600 as being the ideal solution for our very specific sample cutting requirements – generally small samples, 4 to 24 layers in thickness and within working dimensions up to 170 by 250 mms, hence our choice of the 500 model with its larger working area. Learning how to operate the unit has been quite intuitive and although not as yet in constant demand it undoubtedly will speed up our cuttingrequirements once student projects fully resume’.

The installation of the machine did present both the technical team and Compcut’s Kevin Tappin with some particular logistical issues in moving the unit through the designated building and into the laboratory where it was to be housed! – A process that involved the dismantling of doorframes and the temporary removal of some of the Compcut’s outer parts!

Once finally settled into its new home, the machine was commissioned on campus with help from Compcut’s Kevin Tappin, who also provided initial operator training and guidance. [All following strict social distancing guidelines]

Technical Manager, Dave Wood comments, ‘The challenging circumstances brought about by Covid have to a certain extent reduced our planned use of the saw, however, its has never the less been able to establish itself as a vital resource for the cutting and machining of the composite materials used across all our activities and we have been more than satisfied with its performance.’