Success at CTE

Following our recent renowned trial to evaluate the highest-grade composite materials in the Compcut Challenge, the achievements of the team at Sharp & Tappin with its line of composite cutters proceeds to grow with the company’s recent accreditation from Composite Test and Evaluation (CTE), for yet another major success in the Compcut Saws’ ability to outperform competitors and show results at a far quicker rate.

CTE comes fully equipped to test the latest composite, adhesive, and other non-metallic materials and components, with a wide array of evaluation services and equipment that Compcut material cutters have greatly supplemented. Two Composite Plate Saws (the Compcut CPS 200 and CPS 1000) are currently in use by the centre, including a Precision Composite Router (PCR 300) that all make up most of the facility’s equipment for delivering high quality specimen manufacturing.

CTE has many years of experience in evaluating parts for industries such as aerospace, construction, automotive, and environment, testing non-metallic materials for over ten years and upholding a deep and meticulous understanding for composite material tensile strength, durability, and finish against traditional metals.

Utilising Sharp & Tappin’s range of Compcut machines, Composite Test and Evaluation confidently offers reliable, cost-effective, and timely qualifications for a variety of composite samples—materials relevant to our Compcut challenge.

A Cut Above the Rest

Our Compcut saws have gained exceptional results in recent tests at CTE. In just 11 hours, CPS machines were able to efficiently cut 842 composite specimens—that’s 1 specimen that was machined and ready to test every 47 seconds. In comparison, the time in which to cut the same specimens from a manual saw, such as a modified tile cutter, would take more than 5 minutes per specimen when accounting for setup and post preparation of the composite material.

From previous tests conducted for the National Composites Centre (NCC), in which the Precision Composite Router 500 was used to cut dog-bone shaped specimens from Ceramic Matrix Composite material (CMC), Sharp & Tappin has set the standard for clean and reproduceable finishes at Composite Test and Evaluation, with a near zero scrap rate.

CTE initially tested the Compcut machines before overwhelming results in successful trials was followed by their subsequent purchases. Paul Yeo, Managing Director of CTE, has spoken about Compcut’s innovation; “We recently machined 240 laminates into 3840 specimens and did not lose one specimen due to it being out of tolerance. As well as the reproducibility on show, these specimens were cut into a variety of component types, all varying in size and shape, reaffirming the great efficiency Sharp & Tappin’s Compcut machines provide.” The specimens produced on the saws exceeded requirements of the common international standards that CTE perform testing to.

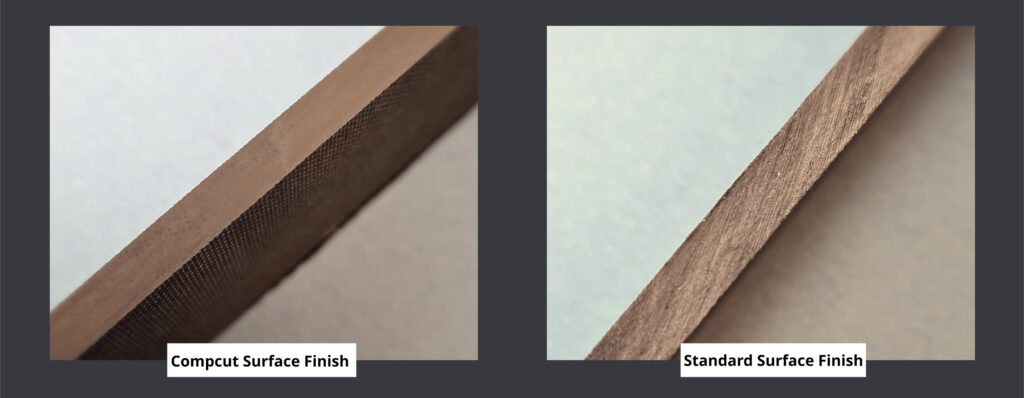

Our latest generation of Compcut saws perform at such a high quality of manufacture that post preparation of composite materials, usually made to remove machining marks, is not required as the Composite Plate Saws leave exceptional edge finish in half the time preparation takes. CTE are thus able to offer its customers significant cost benefits at a reduced timescale, improving the flow of manufacture and increasing the scale of production.

“The 3840 specimens we recently tested provided us with sufficient results to compare against our operating processes,” said Paul. “It saved us 4 weeks of labour and programming time due to the redundancy of post preparation. The time it takes to cut composite materials has now been greatly reduced, meaning customers will not only have their requests seen to quicker, but will receive their products on time and with the highest quality of cutting precision.”

Shining Example for a Bright Challenge

The Compcut Challenge is well underway. Already, institutions such as the National Composites Centre and Composite Test and Evaluation have seen first-hand the amazing effects of utilising Compcut saws for fast, precision cutting of composite materials. The machines are simple to use with little training required to operate. As CTE observed, previous experience in CNC machining was not essential to learning how to operate the Compcut cutters, with trials showing specimens could be produced with only an hour’s worth of training. Our machines, shown to be easy to learn and operate, can now be offered to wider range of industry experience levels, allowing all customers who choose Sharp & Tappin will be given the best cutting solution for their budget.

We are continuing to encourage material designers to submit their materials to be put under the blade for the ultimate tests of Compcut application, including:

- Safety of apparatus

- Clean-up after cutting

- Cutting speed

- Ease of use

- Cost-effectiveness

- Consistent accuracy

- Reduction of waste and debris

The team hopes that the test results conducted from Composite Test and Evaluation will reinforce the live demonstrations that are taking place across the next few months, including live builds and samples at JEC World from 3rd to 5th May in Hall 6, Stand S60.

Compcut composite material cutters remain the most efficient cutting saws for non-metallic materials, with high cutting speeds delivering clean and exquisite finishes for a plethora of materials and specimens. With the assurance of the UK’s leading evaluator in composite components, Sharp & Tappin are confident that CTE’s results will support the challenge’s assertions.

To take part in the Compcut Challenge

Register here: www.compcutacm.com/compcut-challenge.